Race Timing Series: Part One

Content

- Race Timing Methods

- 4 Types of Race Timing Systems

- Terminology

- Variable Chart

- Do-It-Yourself Systems

- Out-Of-The-Box Systems

- Conclusion & Where to Learn More

Race Timing Methods

Race Timing is the practice of recording the individual times of each participant in a race. Race Timing is not only used for recording the times of runners in a foot race such as a 5k or marathon, but is also used in animal races, bicycle races, car races, or any event that requires accurate timing. Companies that time races are known as Race Timers, and this community is made up of many types of business, from amateur timers to professional timing companies. Some companies provide this service as a side job/hobby, while other companies time hundreds of races a year with a full-time staff. Both types of companies can provide finish times, lap times, and other services like photos, printed results, and category results.

Keeping accurate times can be accomplished via a few different methods. Below are some of the most popular methods used today.

-

Manual/Written – A stopwatch and paper can effectively be used to time small races by simply keeping time and writing down bib numbers as participants cross the finish line.

-

Photo Finish – For fast-paced races, such as horse & car races, most events rely on specialty video cameras placed at the finish line that can capture over 120 images per second with timestamps.

-

Passive RFID –Passive RFID is one of the most popular methods for timing races. Passive RFID involves placing an RFID tag on each participant which is read by an antenna positioned at the finish line for extremely accurate results.

-

Active RFID – A similar setup as Passive RFID, Active RFID involves tagging participants and standing up a system at the finish line that reads each tag. Active RFID tags can be read at further distances than Passive RFID, but are much more expensive because each tag contains a battery.

-

NFC RFID – NFC is a type of RFID technology with very limited read range of only a few inches. This type of RFID can be used in races that have a ‘touch’ aspect, like races involving batons or touching checkpoints for interactive races like scavenger hunts for example.

Passive UHF RFID is one of the most popular way to time races, the rest of these three-part series will focus primarily on Passive RFID.

Timing races with Passive UHF RFID is also called Chip Timing, which refers to the process of receiving the data written to the Integrated Circuit or “Chip” within each RFID tag and the reader time stamping the data upon arrival. RFID Chip Timing is one of the most popular methods of timing races because of the accuracy, low tag cost, and average read range of 10 – 20 feet. An RFID system is an upfront investment, that typically starts around $1,500 for the smallest possible system, and if properly cared for, will last for years to come.

Because of its popularity, the rest of this three part series will focus primarily on passive RFID.

4 Types of Race Timing Systems

A basic chip timing system is usually composed of an RFID Reader, 2-4 RFID Antennas, 2-4 RFID Cables, RFID Tags, and Race Timing Software. Before diving into choosing the equipment for a system, it is important to understand the software options available.

When thinking about purchasing or building an RFID Race Timing system, one of the first things to consider is the software. The type of hardware and tags used with your system will depend greatly on the software option you choose. There are pros and cons to each method, and the more you know about each, the more informed decision you can make when deciding to buy or build an RFID Race Timing System.

There are two basic types of RFID Race Timing Systems - Do-it-Yourself (DIY) and Out-of-the-Box Software. Out-of-the-Box Software is further subdivided into three types: One-Time Fixed Cost, Pay-As-You-Go, and Contract Systems.

Do-It-Yourself (DIY) System

A DIY System simply describes a system that starts with custom software developed specifically for your application. Typically, it is best to test with RFID hardware and understand how the system works as well as what SDK/API options are available to them. After hardware testing and creating the software, if the hardware and tags are not already purchased, they will need to be purchased from RFID resellers or distributors to fit your software’s needs.

Out-Of-The-Box Systems

One-Time Fixed Cost System – A one-time fixed cost system starts with purchasing software upfront as a one-time cost. Typically, with these systems, the software developer will provide a list of compatible RFID readers from which the timer can choose. Many times, they will also provide recommendations on antennas and RFID tags, but typically these companies will provide software only and the RFID hardware and tags will be purchased from other RFID resellers or distributors.

Pay-As-You-Go System – A pay-as-you-go system starts with purchasing software that might have a small upfront cost, but, will also be billed monthly or yearly as a software licensing fee. Companies that sell this software will provide recommendations on antennas and RFID tags based on the success of other users and will suggest where to buy RFID hardware and tags.

Contract System – A contract system starts with purchasing an all inclusive system that includes software, hardware, and tags. There is usually a one-time upfront fee for the equipment and software and recurring costs associated with purchasing tags and additional equipment from this company.

Terminology

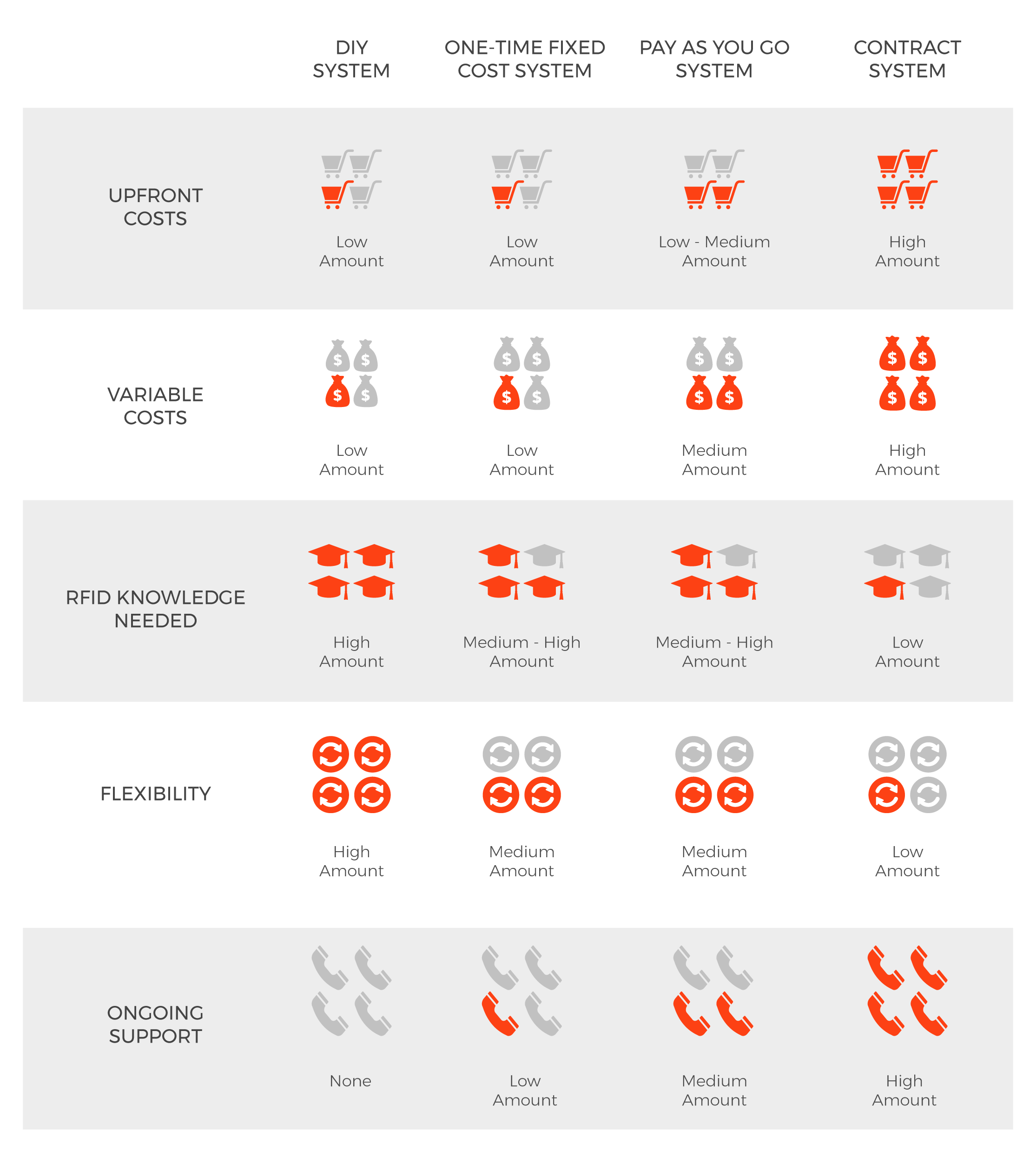

Before comparing the 4 types of systems, let’s outline how we will analyze them - in terms of Upfront Costs, Variable Costs, Upfront RFID Knowledge Needed, Overall Flexibility, and Hardware Support.

-

Upfront Costs - The upfront costs in an RFID race timing system are generally defined by the costs of purchasing the initial system. Ongoing costs, like licensing fees and disposable RFID tag costs, are not included in the calculation. Some systems have high upfront costs but low variable costs.

-

Variable Costs – Variable costs are ongoing costs, usually for the life of your system like licensing fees, disposable RFID tag costs, and replacement equipment. Some systems have low upfront costs, but high variable costs.

-

Upfront RFID Knowledge Needed – Upfront RFID Knowledge Needed is the amount of RFID background and knowledge the buyer should have before purchasing the system. In DIY systems, for example, the buyer must either already have a working knowledge of RFID or be willing to conquer a steep learning curve in order to set up and create the software and system. Also, the buyer must have programming capabilities or know someone that does in order write code to interact with the RFID system. On the other hand, Contract Systems do not usually require a large amount of RFID knowledge before purchasing because they usually include training courses, videos, and other training aids.

-

Overall Flexibility – Overall Flexibility includes both software flexibility and hardware flexibility. The general level of flexibility of a race timing system is determined by the race timer’s ability to adjust his/her system in response to race changes, environmental changes, or changes in preference. Systems with the highest level of flexibility, such as DIY systems, are able to be altered over time into a custom system that fits you and your races.

-

Hardware Support – The level of Hardware Support varies greatly depending on the type of system because most RFID readers include manufacturer support. However, since Out-of-the-Box Systems contain a software component, they typically include various levels of ongoing support.

Variable Chart

Software Overview

Do-It-Yourself Systems

A Do-It-Yourself RFID Race Timing System is different from an Out-of-the-Box system because the purchaser develops the software (or contracts out the developing to a software engineer). For some, creating a custom race timing software can be very rewarding because it can be customized to perform exactly how you see fit. DIY Race Timing Systems allow the buyer the freedom to mix and match different pieces of hardware to create the “perfect system” for his or her needs. Most problems with a DIY system usually stem from the lack of knowledge of both RFID and software it takes to build and support a system. Because this system is pieced together, there should always be someone at each race with knowledge about each product and the software in case of problems.

DIY systems usually cost less than Out-of-the-Box systems, but it is important to take in consideration the cost of developing the software, or the cost of paying someone to do so. One of the pros of using a DIY system is the ability to change the system at will based on additional needs. If there is a change in read zone width or height brought on by environmental changes, DIY systems have the ability to add or subtract pieces of hardware in order to provide the exact amount of coverage for the new course. Such flexibility with both the amount and type of hardware makes this type of system very popular. Furthermore, although there can be significant upfront costs associated with designing your own software, this option can provide users with substantial functionality and flexibility to do things like incorporating cameras or building custom API integrations to other software systems. Most notably, in the long run, a DIY system can have very low variable (per runner) costs because you can buy tags on the open market and avoid software licensing fees. Thus, in high volumes, a DIY Race Timing System can be economical.

"The beauty of developing your own software is the flexibility to tailor your race to your specific customer and race director. The only downside to this would be that software development takes time; however, once it is complete, you have no licensing fees. This is a piece of intellectual property that you own and can sell or provide as a service." - Rick Williams, atlasRFIDstore

Out-Of-The-Box Systems

Companies who make Out-of-the-Box Race Timing Systems are essentially software companies. They may provide a large range of services that help enable them to sell their systems, but a system’s unique qualities are usually derived from its software. Most companies that sell race timing systems have not developed their own RFID hardware (with a few exceptions). Instead, they re-purpose general RFID readers, antennas, cables, and tags into branded, specialty race timing equipment. One caveat is that the customized cases in which many companies house their RFID readers have been designed by them. These cases are customized to contain specific elements like batteries, wireless routers, or even cell receivers to enable networking. There are three main variations of Out-of-the-Box Race Timing Systems that are differentiated by their pay structure – One-Time Fixed Cost Systems, Pay-As-You-Go Systems, and Contract Systems.

"An Out-of-the-Box Race Timing System is great for people who don’t have the time or the skill-set to develop or test software. They need a quick, easy solution. The biggest downside to this system is that you will have to pay a company upfront fees and possibly on-going licensing fees." - Rick Williams, atlasRFIDstore

Three Types of Out-Of-The-Box Systems

One-Time Fixed Cost System

One-Time Fixed Cost systems are frequently hardware agnostic, meaning that the buyer purchases software rights that can work with a variety of RFID hardware options. Specifically, the software communicates with the RFID reader using LLRP, or Low-Level Reader Protocol, which enables it to work with most enterprise-level RFID readers. Companies that sell these systems cater to a slightly more tech-savvy customer who is capable of sourcing RFID hardware and tags and is willing to take ownership of the race timing process. Once these systems are purchased, there are no ongoing software costs or licensing fees. The only variable cost is likely to be the cost per tag (if disposable tags are used).

Pay-As-You-Go-System

Pay-As-You-Go Systems may or may not be hardware agnostic. Some companies sell their software in a complete system that includes hardware, while others are content to only sell software and allow customers to choose their RFID hardware. These systems do not have an associated annual services contract or support fee, but they do charge a software licensing fee each time that the system is used. One advantage that these systems have over a “One-Time Fixed Cost” system is that the software company has an incentive to support their products and continue to improve them. This is because a significant portion of their revenue comes from the customer’s continued satisfaction.

Contract System

This type of system is a full services contract between the race timer and the race timing company. This means that the system is associated with significant training and ongoing support while also frequently locking down the race timer to using tags and hardware purchased directly from the race timing company. Because you must use the company’s tags and hardware, both fixed and variable costs for this option may be high, but they are great options for “high-stakes” races where professional runners or significant cash prizes may be distributed.

Conclusion

This concludes part two of our RFID Race Timing eBook Series, covering components in a Race Timing System, how to choose each piece for your ideal system, and a general look at a system on race day. Up next, part three will cover tagging race participants, popular tagging methods, planning for a race, race day information, and how to mitigate potential problems.

For more information on all things RFID, checkout our website, our blog, our in-house ebooks, and our YouTube Channel. If you have specific questions about your Race Timing System, chat with us on our website, send us an email, or give us a call.