RFID Laundry Tags - Attachment and Use

Tracking laundry, garments, and uniforms with RFID tags is one of the best ways to keep track of expensive costumes and linens. Tracking these items via RFID also helps to prevent theft while adhering to budget concerns. Whether the company is in the hospitality, healthcare, fitness, or the rentable retail industry, every textile company has a need to reduce replacement costs and extend the life of the garment or linen. By attaching an RFID tag to individual items, companies can manage inventory and keep track of each item’s lifespan. This allows companies to make informed decisions about adding or removing certain items depending on wear and tear.

RFID Laundry Tags

Once a company decides that an RFID laundry tracking system can benefit them, the next step is to decide on an RFID laundry tag. There are three types of laundry tags which are categorized by how they attach to a garment:

- Sewn On

- Heat Sealed

- Inside a Pouch

Before going into detail about attachment methods, here is some general information about RFID laundry tags.

General Specifications

In order to be used on linens and garments, RFID laundry tags must be able to survive the water, heat, and pressure experienced in washing machines and dryers. Tags must be waterproof, able to survive temperatures of around 120° F, or 48° C, and able to survive least 1 bar of pressure. Due to the rigorous process of the wash cycle and exposure to items like detergent and chemicals, most RFID laundry tags have a specified lifespan of around 200 wash cycles, or 3 years.

Depending on their size and the antennas being used in the application, RFID laundry tags can typically be read between 2 and 7 meters away. A smaller tag such as the Invengo MuTRAK has a footprint of only 7 x 7 x 1.4 mm, but can only be read from up to 10 cm away. Read distance and form factor are two very important variables to consider in every RFID application, and especially for laundry tracking.

Attachment Methods

As mentioned above, there are three common ways to attach RFID laundry tags to ensure their security during the laundering process – tags can be sewn on, heat sealed, or secured inside a pouch.

Sewn On

RFID laundry tags that are made from Fabric, like the Invengo LinTRAK-Slim, the Invengo LinTRAK C15, and the HID Global LinTag 200, are all designed to easily be sewn on linens and garments. Sewing the tag directly on the material is the fastest way to attach an RFID tag, as using a heat sealer or creating a pouch takes more time to complete.

Heat Sealed

Most RFID laundry tags can be attached to fabric via heat sealing. Heat sealing is the process of sealing plastic via heat and pressure and requires the use of a heat sealer. Heat sealers vary in price depending on their size, but usually start at around $80. Heat sealing is an ideal tag attachment method for when sewing is not an option or sewing looks unfinished.

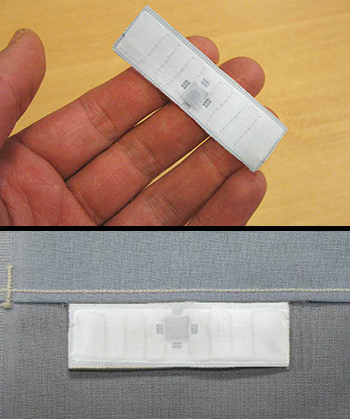

Inside a Pouch

If an item has extra fabric or multiple layers, an RFID tag can be placed inside a small pocket of fabric. The fabric is then sewn up so that the tag is hidden. The pouch attachment method can also be achieved by slipping an RFID laundry tag into the hem of a garment. However, the hem must be defined so that the tag cannot continually move through the garment.

RFID Hardware Setup

When setting up a new RFID laundry tracking system, it is usually very helpful to take a look at how the current laundry system operates and adapt the new system to the old standards. Companies that have adopted an RFID laundry tracking system have created read points in the following locations:

- In a doorway to read tags upon entering or exiting the laundry area

- On the ground for tagged laundry carts to pass over

- Above or below a laundry sorting or folding table

- In Laundry chutes or on conveyor belts

Let’s take a more detailed look at one of the most popular laundry tracking setups, which is a system with a portal/doorway read point. Setting up an RFID portal in the doorway of a laundry room can be accomplished by mounting antennas on either side of the doorway at the level laundry carts will pass. Testing is essential to determine the best height, angle, and number of antennas needed. Testing should initially involve one or two antennas, and then additional antennas can be added depending on the size of the doorway and read rates during testing.

A fixed RFID reader can be positioned either above or on either side of the doorway, and the reader can either connect to a host PC via a local area connection or be setup on a Wi-Fi network in order to send the reads back to the software. The software on the PC can then be written to timestamp the RFID tag reads, document if the linens are entering or exiting the laundry room, and alert employees when linens have not been read in a certain timespan.

In addition to a fixed system that counts linens moving in and out of the laundry area, a mobile handheld reader can be used to scan rooms with missing linens or to add or remove linens from their inventory.

Conclusion

If you’d like to learn more about all things RFID, check out our website, our YouTube channel , comment below, or contact us.

To read more about laundry tracking applications, check out the links below!